The Six Levels of Independent Performance Testing

1. Reaction To Fire – A-Rated

Every type of building material has its own reaction to fire which is defined on the basis of tests carried out according to the British Standard Institution: EN13501-01, a specific classification system which goes from A (non-flammable product) to F (unclassified product). These reference parameters primarily take into consideration the combustibility level, fire propagation velocity and development of heat per unit of time.

Brickspan® fire resistant properties are designed to meet specific fire engineering criteria, which significantly reduce the risk of fire.

Tested by Exova International Warrington laboratory to a fire rating of A2. (www.exova.com)

2. Excellent Breathability

Vapour permeability (commonly referred to as breathability) is a material’s ability to allow water vapour to pass through it. This is often confused with the concept of withstanding the ingress of bulk water. The difference is that bulk water is moisture in liquid form whereas water vapour is a gas. The amount of moisture that moves and the method of movement are also significantly different. A single drop of water consists of thousands of molecules.

In general, this concept can be compared to a train full of people who travel together. Just imagine the passengers trying to get up and off the train through the door – all at the same time. They won’t fit, so no one gets on the train or off it. But just suppose the passengers spread out, and in an orderly fashion and one-by-one, they attempt to exit the train. Some of them would get out.

In just the same way, when thousands of molecules of water get behind architectural cladding, they can’t fit through the small pores in the façade covering. When you have moisture vapour in your wall, one molecule can break away from the pack and is able to escape by diffusion. When a material allows these individual molecules to pass, it is called vapour permeability.

This is one of the major differences between Brickspan® and other acrylic, resin, cementitious and traditional cladding products.

Tested by Lucideon, an international, independent material testing and technology laboratory to ETAG 004:6.1.3.4 and to ETAG 034:2013. (www.lucideon.com)

3. Colour Fading and UV Resistant

The patented Brickspan® composition and manufacturing technology ensures that tone fading or colour loss is not apparent over time.

Testing these requirements is exceptionally specialised and carried out by means of Colourimeter readings which are taken using a laboratory colour spectrometer space system. This defines the colour of an object as a 3 dimensional co-ordinate within a colour sphere exposed over time to heat and UV radiation.

The L co-ordinate represents ‘lightness’ and runs from 100 (complete lightness) to 0 (complete darkness), where a is the red direction, –a is the green direction, +b is the yellow direction and –b is the blue direction. Lab readings taken are an average over a 2mm spot size in each case.

Following 1000hrs of intensive accelerated UV weathering using cycle 1 method ‘A’, no effects of Ultra Violet (UV) radiation or significant colour changes were detected either by eye or with the Laboratory Colourimeter.

Tested by Materials Technology Limited in accordance with BS EN ISO 16474- 3 Cycle 1 method “A”. (www.drb-mattech.co.uk)

4. Lengthy Product Life and Whole Life Performance

Using a set of accelerated weathering tests simulating real European climatic conditions, a 6 square metre, Brickspan® Fast Fix façade was constructed and exposed to the sun’s cycles of heat, rain and freeze-thaw, over a monitored period of 30 days in a Laboratory environment using an acclimatisation chamber.

The purpose of durability tests within European Technical Approval Guideline (ETAG) guidance is to determine that there are no technical or aesthetical defects of cracking, blistering, peeling or delaminating on the surface of the product during the buildings expected life span. These stringent tests provide an expected life span of no less than 35 years.

Tested at Lucideon, independent material testing and technology laboratory by complying with ETAG 004:6.1.3.2.1. (www.lucideon.com)

5. Resistant – Category 1

To ensure public safety, high-rise buildings require water-tightness, wind resistance and high impact capability which take account of their individual height and location. The Brickspan® Fast Fix has been successfully tested for Category 1 impact resistance and weather-tightness using controlled British Standards and classifications for Building Envelopes. Water-tightness, The Centre for Window and Cladding (CWCT)/BS EN 12154: 600 and Wind Resistance CWCT/BS EN 13116: ±2400 (Pascal’s serviceability dynamic) were both achieved along with High impact Category CWCT TN76: Class 1.

Tested at VINCI Technology Centre UK Ltd. (www.technology-centre.co.uk)

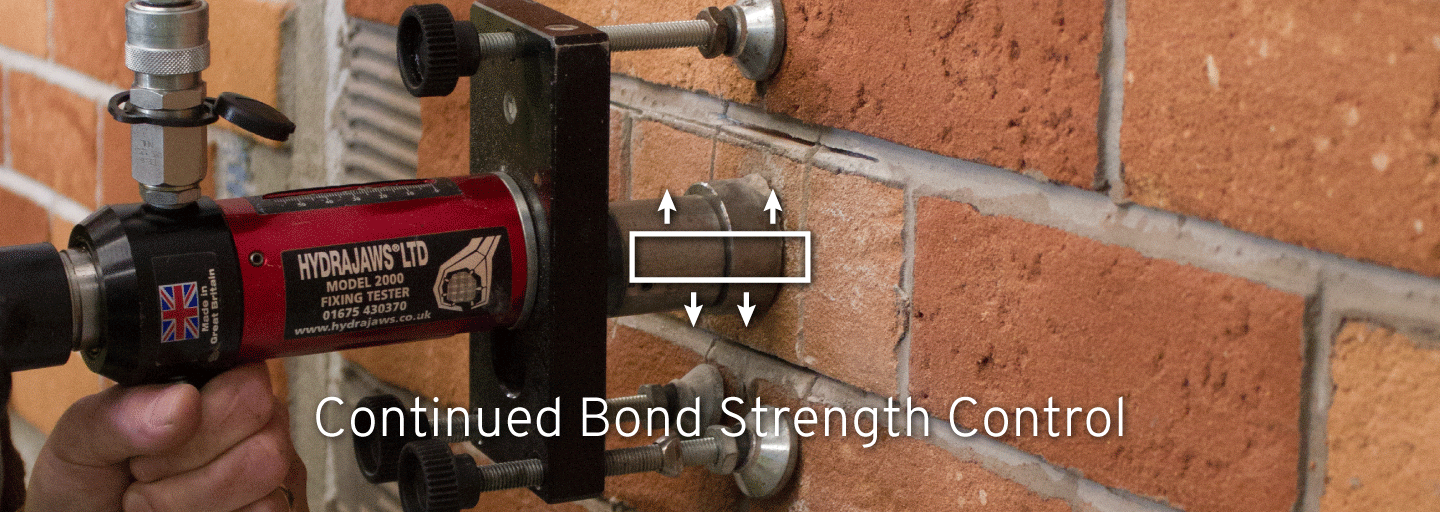

6. Excellent Bond Strength Control

Brickspan® has tested a range of compatible adhesives on various substrates and wall systems. Adhesive strength tests were performed according to the pass standards of ETAG-required guidelines and were based on direct pull-off strengths using a compressive test machine, while working in the opposite direction with a digital hanging scale attached.

These tests are carried out before, during and after accelerated thermal chamber weathering to provide total bond characteristics under ETAG: Pass standards for 004:6.1.4.1.1.

Tested at Lucideon, independent material testing and technology laboratory. (www.lucideon.com)

Downloads

To print or view any of the documents please click on the links below.